ARASH HUMANOID

ARASH HUMANOID

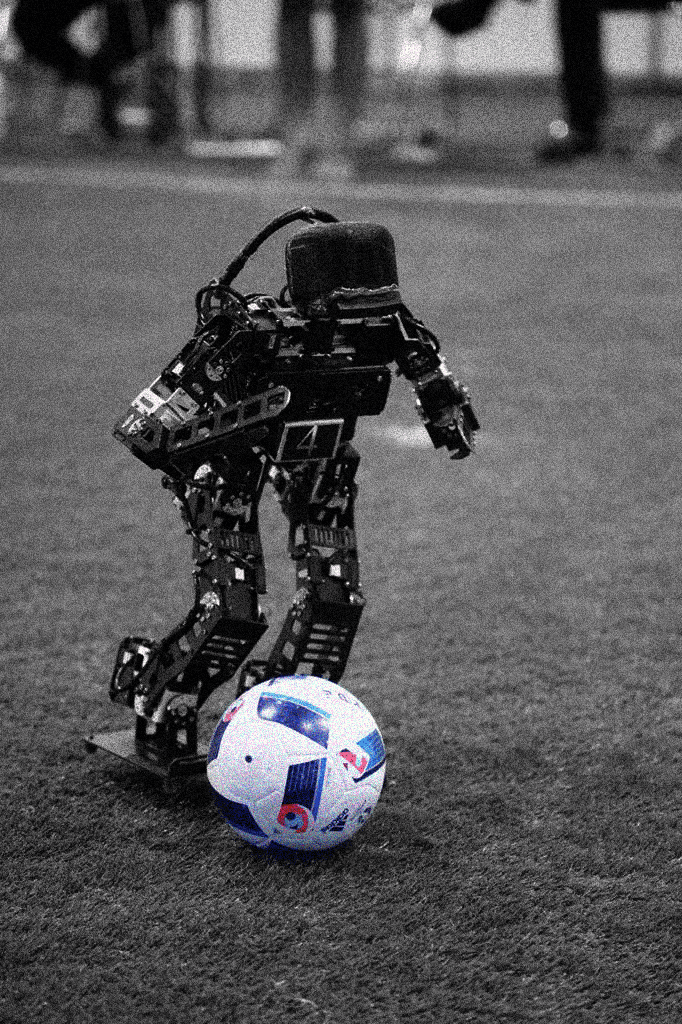

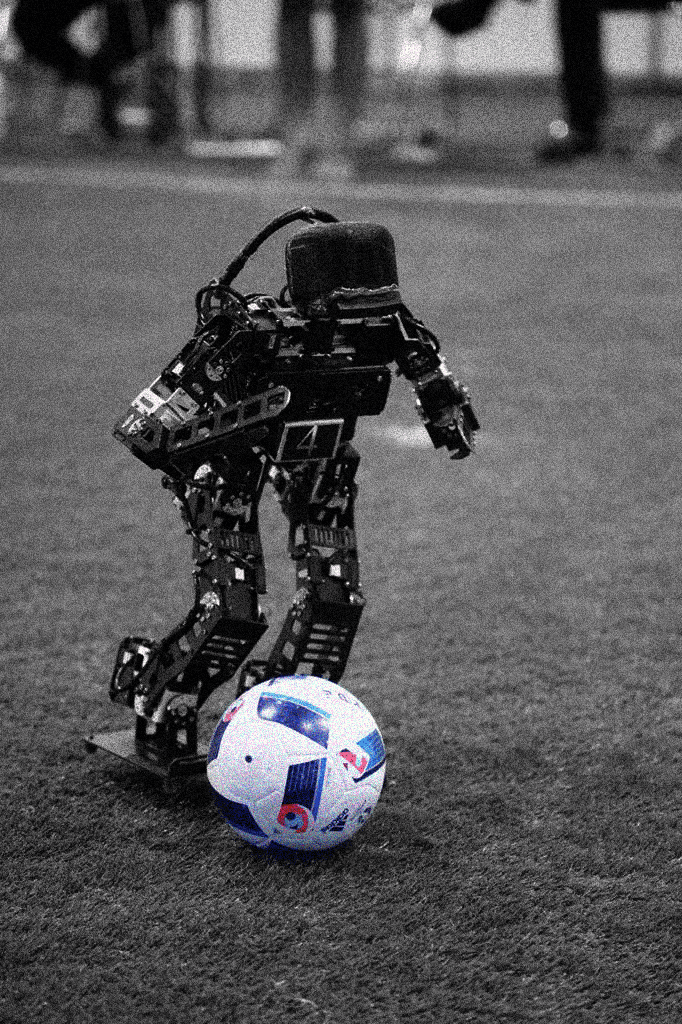

Arash is a humanoid soccer robot built in the MRL Humanoid Soccer League (HSL) at QIAU. Our goal was to create kid-size and teen-size players that could walk, kick, and handle RoboCup technical challenges while staying easy for a student team to maintain. I worked across mechanical design, control, and testing to keep the robot reliable on the field.

Arash is a humanoid soccer robot built in the MRL Humanoid Soccer League (HSL) at QIAU. Our goal was to create kid-size and teen-size players that could walk, kick, and handle RoboCup technical challenges while staying easy for a student team to maintain. I worked across mechanical design, control, and testing to keep the robot reliable on the field.

Arash is a humanoid soccer robot built in the MRL Humanoid Soccer League (HSL) at QIAU. Our goal was to create kid-size and teen-size players that could walk, kick, and handle RoboCup technical challenges while staying easy for a student team to maintain. I worked across mechanical design, control, and testing to keep the robot reliable on the field.

Arash is a humanoid soccer robot built in the MRL Humanoid Soccer League (HSL) at QIAU. Our goal was to create kid-size and teen-size players that could walk, kick, and handle RoboCup technical challenges while staying easy for a student team to maintain. I worked across mechanical design, control, and testing to keep the robot reliable on the field.

HUMANOID SOCCER LEAGUE (HSL), MECHATRONICS RESEARCH LAB, QIAU

Year

AGU 2017-JAN 2018

Category

MECHANICAL DESIGN · SIMULATION

Live Project

View Now

Collaborative Design

Collaborative Design

Collaborative Design

/// Every successful field run comes from iterative testing and redesign across multiple teams. My contribution focused on mechanical design, where I refined structure and motion while collaborating with electronics and software to ensure each mechanical decision supported their sensor, control, and integration needs.

/// Every successful field run comes from iterative testing and redesign across multiple teams. My contribution focused on mechanical design, where I refined structure and motion while collaborating with electronics and software to ensure each mechanical decision supported their sensor, control, and integration needs.

/// Every successful field run comes from iterative testing and redesign across multiple teams. My contribution focused on mechanical design, where I refined structure and motion while collaborating with electronics and software to ensure each mechanical decision supported their sensor, control, and integration needs.

It’s not just me, it’s all of us!

MRL-HSL is made up of three main sub-teams

MRL-HSL is made up of three main sub-teams

MRL-HSL is made up of three main sub-teams

Electronics

Software

Mechanics

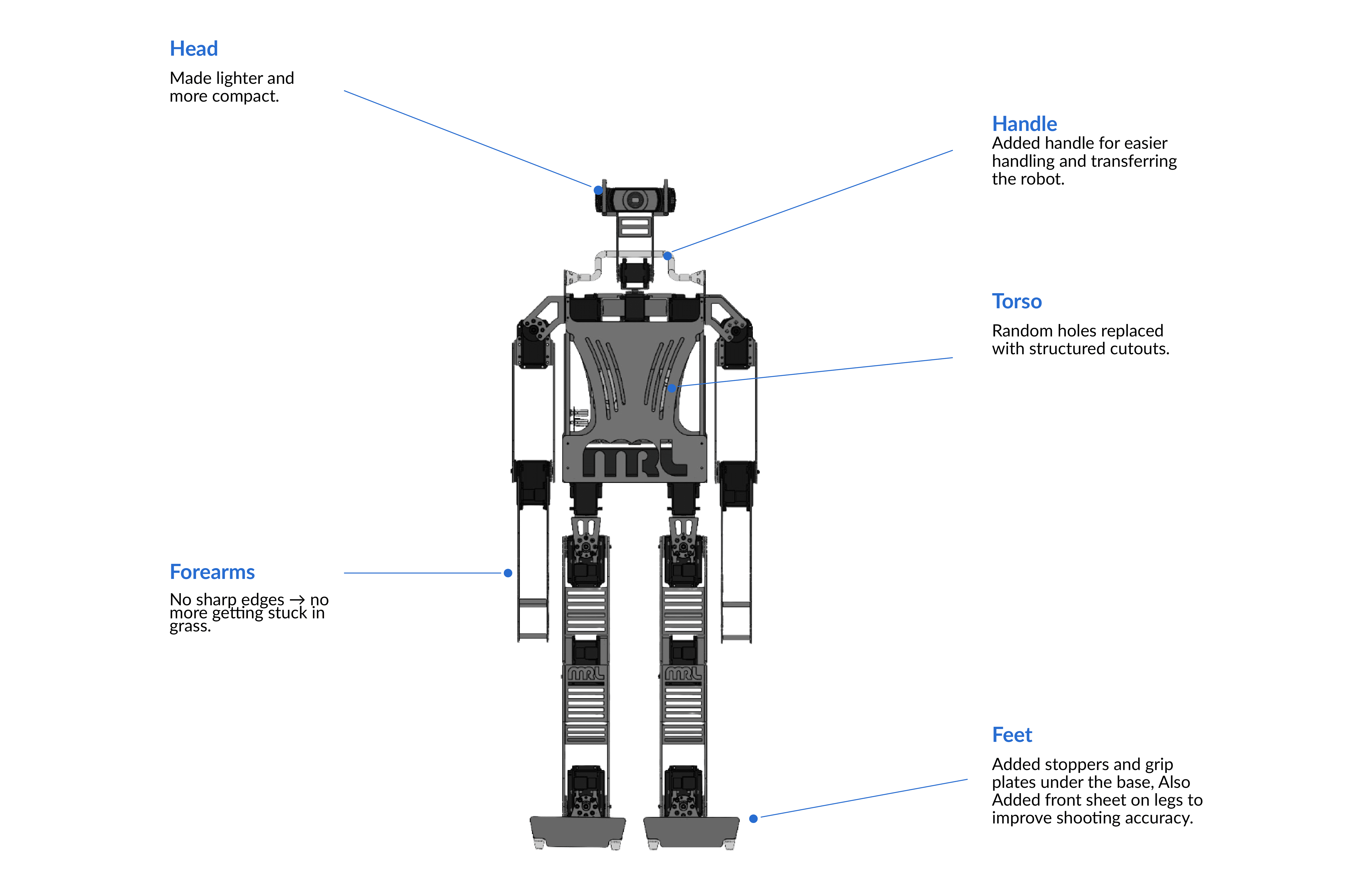

We began with a kid-size humanoid robot, but to compete in the Teen Size category we needed a completely new platform. I designed this robot by drawing inspiration from our kid-size model, as well as NAO, DARwIn-OP, and human golden-ratio proportionOPs.

The kid-size platform gave us a clear baseline for joint alignment, actuator range, and overall body proportions. Analyzing its performance on grass, weight distribution, and kicking stability helped define the mechanical requirements for the teen-size robot.

Kid-size robot

We began with a kid-size humanoid robot, but to compete in the Teen Size category we needed a completely new platform. I designed this robot by drawing inspiration from our kid-size model, as well as NAO, DARwIn-OP, and human golden-ratio proportionOPs.

The kid-size platform gave us a clear baseline for joint alignment, actuator range, and overall body proportions. Analyzing its performance on grass, weight distribution, and kicking stability helped define the mechanical requirements for the teen-size robot.

Kid-size robot

Foundation Research

Foundation Research

Foundation Research

I explored screw types, actuator options, and material behaviors, selecting the final motor model with the electronics team. The body material had to resist deformation, avoid reflective surfaces that could disrupt vision systems, and still be easy to machine and polish. These early decisions guided the structure of the teen-size robot.

I explored screw types, actuator options, and material behaviors, selecting the final motor model with the electronics team. The body material had to resist deformation, avoid reflective surfaces that could disrupt vision systems, and still be easy to machine and polish. These early decisions guided the structure of the teen-size robot.

I explored screw types, actuator options, and material behaviors, selecting the final motor model with the electronics team. The body material had to resist deformation, avoid reflective surfaces that could disrupt vision systems, and still be easy to machine and polish. These early decisions guided the structure of the teen-size robot.

6061-T6 aluminum

6061-T6 aluminum

6061-T6 aluminum

Studying Existing Platforms

Mechanical Joint Hardware

Mechanical Joint Hardware

Actuator Selection

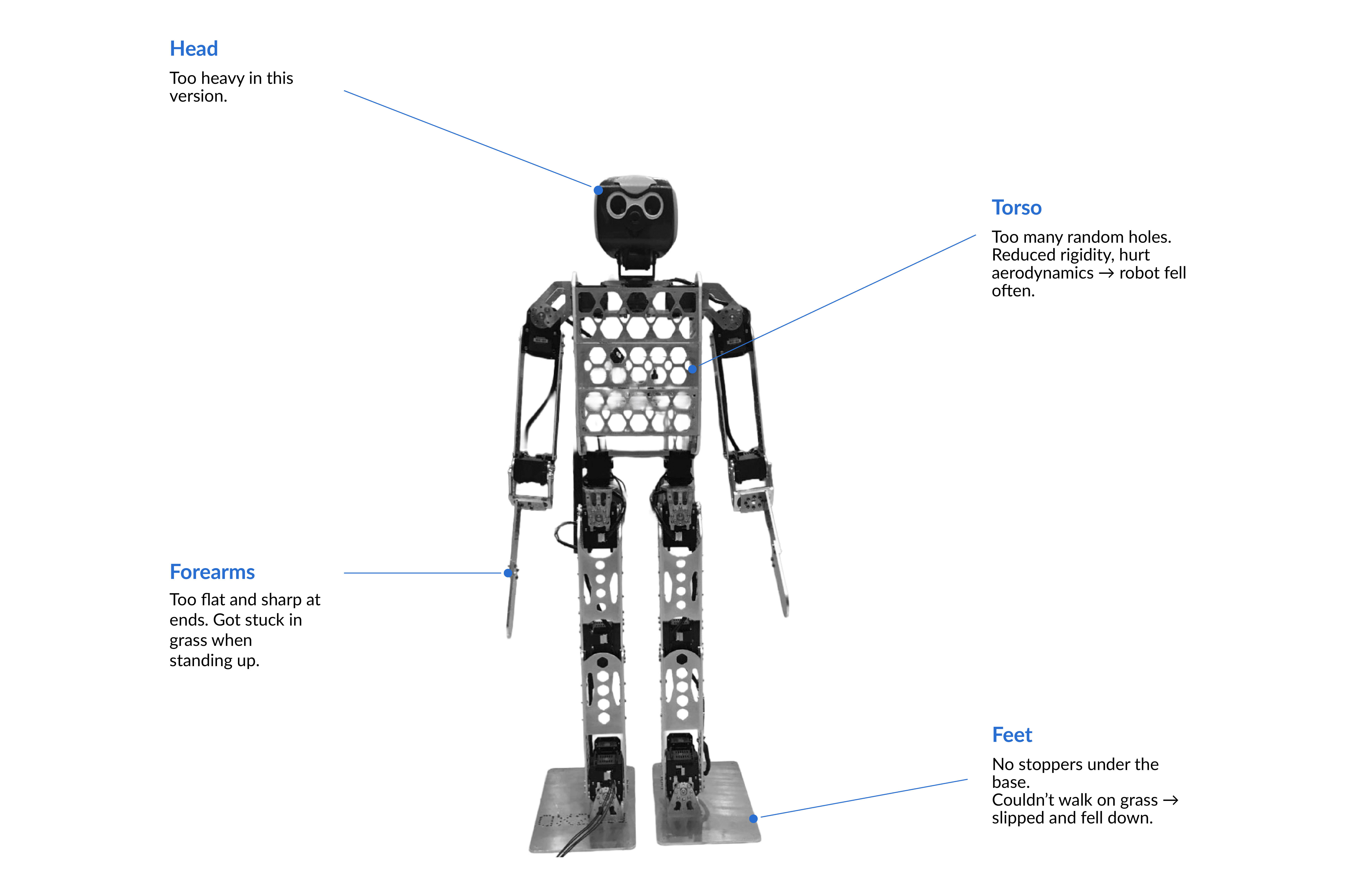

Prototype / Failed Version

Final / Improved Version